Figure 1.

The Saturn V moon rocket and its Launch Umbilical Tower (LUT) on launch pad 39A .

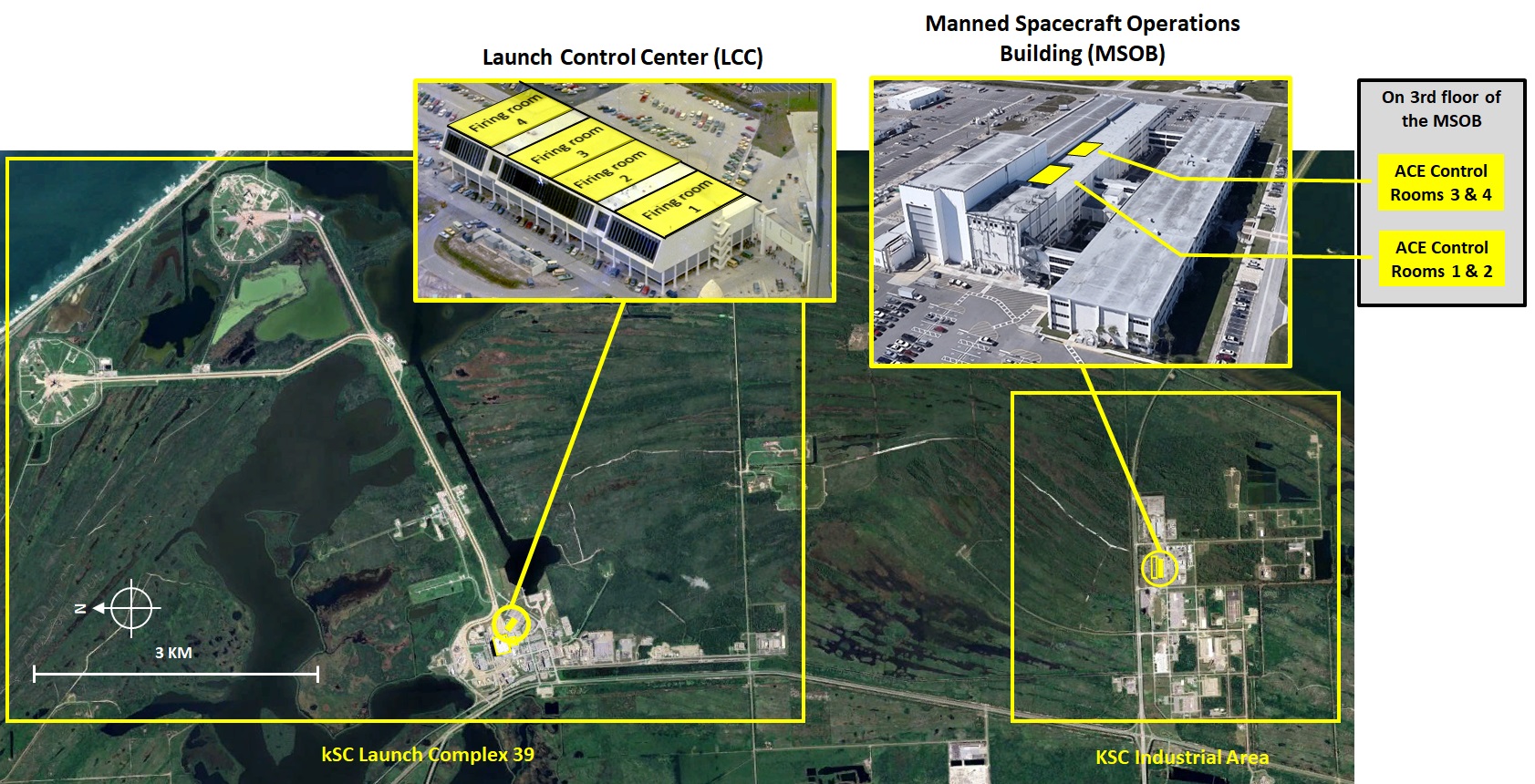

The whole rocket was a complex machine; the LUT and the two-storey-high grey launch platform contained a lot of equipment to monitor the numerous systems in the stack and to prepare the rocket for flight. Figure 2 is a functional system diagram in which it is shown how the Saturn V-Apollo stack was monitored from one of the three firing rooms in the LCC (Launch Control Centre) and from two control rooms in the MSOB (Manned Spacecraft Operations Building).

The first stage (S-IC stage) was running on kerosene and liquid oxygen. Both the second stage (S-II stage) and the third stage were running on liquid hydrogen and liquid oxygen.

The swing arms between the LUT and the launch vehicle were part of the Ground Support Equipment (GSE). The swing arms were used for propellant loading, all kinds of electrical connections, environmental control and vent lines for the fuel tanks filled with liquid hydrogen. The tail service masts and the swing arms nr. 4 through 8 were retracted at lift-off.

This hazardous gaseous hydrogen was burnt in special burn ponds at some distance from the launch pad. The tanks filled with liquid oxygen were vented through vent valves of the three stages in the open air to keep the tank pressure within limits.

The two-storey-high launch platform housed an impressive set of equipment to control the equipment of the launch umbilical tower. A computer system was part of that equipment, which also contained a so-called auto-sequencer, a computer program to control the countdown sequence during which hundreds of parameters of the launch vehicle and of the launch umbilical tower were checked and commands were sent to various systems according to a pre-determined sequence of which the "ignition" was the final command.

Photos: Credit to NASA. Scanning credit to Kipp Teague

|